Aviation

Airbus Commercial Aircraft delivers record performance

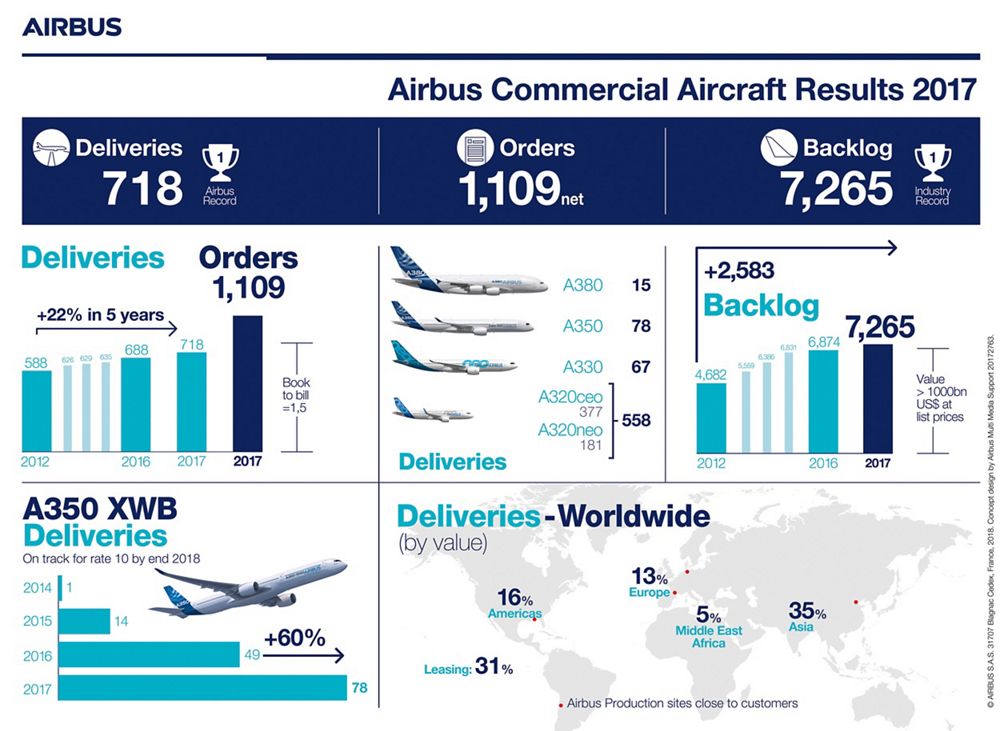

· Total deliveries reached 718 – four percent higher than the previous record

· 1,109 total net orders from 44 customers; Book-to-bill ratio at 1.5

Toulouse, 15th January 2018 – Airbus’ Commercial Aircraft deliveries in 2017 were up for the 15th year in a row, reaching a new company record of 718 aircraft delivered to 85 customers. Deliveries were more than four percent higher than the previous record of 688 set in 2016. The 2017 total comprises: 558 single aisle A320 Family (of which 181 were A320neo – an increase of 166 percent over 2016); 67 A330s; 78 A350 XWBs (up by nearly 60 percent from 2016) and 15 A380s. Furthermore, to cap this resounding annual production achievement, Airbus achieved 1,109 net orders from 44 customers. At the end of 2017 Airbus’ overall backlog stood at 7,265 aircraft valued at US$1.059 trillion at list prices.

Fabrice Brégier, Airbus Chief Operating Officer and President Commercial Aircraft commented: “A new Airbus delivery record coupled with our fifth best order intake wraps up a remarkable year for us. This outstanding achievement is testimony to the dedication of all our teams, and makes the company fitter, stronger and ready for the opportunities ahead.”

With this year’s performance Airbus has steadily built on deliveries year on year – with 15 consecutive years of production increase. From its four A320 Family plants in Hamburg, Tianjin, Mobile, and Toulouse, Airbus is on track to achieve rate 60 per month on single-aisle by mid-2019. Meanwhile, the A350 XWB is equally on track for rate 10 by the end 2018. Airbus’ healthy order intake in 2017 resulted in a ‘book-to-bill’ ratio of 1.5.

There were many industrial milestones achieved by Airbus Commercial Aircraft in 2017, which included: delivery of the 100th A350 XWB; the delivery of the 50th A320 Family aircraft from our FAL in Mobile; delivery of Emirates’ 100th A380; first flight of the A330neo; certification of the A350-1000; first A321neos delivered with CFM and P&W engines; inauguration of the new A330 Completion and Delivery Centre in Tianjin, China, with two first deliveries; and structural completion of the first Beluga XL. On internationalisation, our partnership with China is expanding while our Americas footprint is equally extended. Moreover, in the provision of Services worldwide Airbus is significantly enhancing its local presence to be closer to its customers.

Aviation

Lost Tool Found in Qantas A380 After 34 Flights

An Australian Transportation Safety Bureau (ATSB) investigation recently revealed that a Qantas A380 operated 34 flights with a 1.25-meter nylon tool lodged in one of its engines.

This turning tool, used during borescope inspections to rotate the intermediate-pressure compressor, was left behind during scheduled maintenance at Los Angeles on December 6, 2023. It remained inside the engine until it was discovered by maintenance staff during a subsequent check at Los Angeles on January 1, 2024.

China Takes the Lead in Sixth-Generation Fighters with White Emperor B

The ATSB report highlights two critical lapses. First, maintenance engineers failed to notice the tool during final checks for foreign objects after the borescope inspection. Second, the lost tool procedure was not activated when the tool was identified as missing.

The certifying engineer ultimately cleared the aircraft for service without accounting for the misplaced tool. During the time qantas films the tool was inside, the A380 completed 34 flight cycles, accumulating nearly 294 hours without any noticeable effect on engine performance.

Although the tool was deformed by high-energy airflow within the engine, there was no reported damage to the engine itself. ATSB Chief Commissioner Angus Mitchell commented.

India’s C-295 to Gain Advanced Weapons for Maritime Surveillance

“This incident underscores the importance of following established maintenance protocols. Engineers missed the tool during foreign object checks, and the required lost tool procedure wasn’t started after realizing the tool was missing.”

Following the investigation, the airline issued a safety directive, urging all engineering and tool storage teams to adhere strictly to these protocols to prevent similar incidents in the future.

A qantas spokesperson stated, “While the tool didn’t impact engine performance, we take this incident very seriously. It is critical to follow the correct lost tool procedures.”

-

Aviation2 months ago

Aviation2 months agoBoeing confirms 797: A New Era for Mid-Size Aircraft

-

Aviation2 months ago

Aviation2 months agoMicrosoft Flight Simulator Raises $3 Million to Bring Back the An-225 Mriya

-

Aviation2 months ago

Aviation2 months agoLockheed and Tata Team Up to Build C-130J MRO Facility in India

-

Airlines2 months ago

Airlines2 months agoQantas Engineers Stage Walkout Over Cost of Living Concerns

-

Airlines2 months ago

Airlines2 months agoQatar Citizens Can Travel to the United States Without a Visa

-

Aviation2 months ago

Aviation2 months agoBoeing Offers 25% Pay Increase & Promise to Build Next Plane in Seattle

-

Aviation2 months ago

Aviation2 months agoQatar Airways bans these new Electronic Devices on plane

-

Airlines2 months ago

Airlines2 months agoEmirates Ends 28-Year Singapore-Melbourne Fifth Freedom Route