Aerospace

The 2021 Crystal Cabin Award winners – The Future of Air Travel

The 2021 Crystal Cabin Award winners – The Future of Air Travel: The Aircraft Interiors Expo (also AIX for short ) is an annual three-day trade fair for aircraft cabin interiors at the Hamburg Exhibition Center, it was held virtually on 30 March 2021. It is part of the Passenger Experience Week, during which other trade fairs and conferences on the subject of passenger transport are held.

- Crystal Cabin Award Winner

- Lightweight Materials to Aid Sustainability Targets

- T1-series Seating from Toyota Boshoku

- The maverick project, A touchless future aviation

The 2021 Crystal Cabin Award Winners:

- Cabin Concepts award won by ‘Alice‘, the first completely electric commuter jet, Built by Israeli company Eviation Aircraft. Cabin concept was designed by Almadesign.

- Visionary Concepts award won by Airbus for its Airspace Cabin Vision 2030.

- Material & Components winner is panel based on In-Mold Electronics (IME) from e2ip technologies in association with National Research Council of Canada. It functions positioning of the aircraft seat.

- Greener Cabin, Health, Safety, and Environment winner is Diehl Aviation with its Greywater Reuse Unit. Taking the handwash water (greywater) from the sink and reusing to flush the toilet instead of potable water. It will help to reduce weight and CO2.

- Passenger Comfort winner is Safran Seats with its Modulair S economy seat concept.

- Cabin Systems winner is SOPHY smart trolley system from Safran Cabin. This tiny module can be installed into existing catering trolleys and provides the operator with information on the entire journey of the equipment, from maintenance and cleaning needs.

- In-Flight Entertainment and Connectivity winner is the SAFRAN Passenger Solutions department with RAVE Bluetooth.

- University: The winner in 2020 is University of Cincinnati. Their Coffee House Cabin concept would place a long work table down the center of the plane to allow for productive workgroups. The idea was developed with The Boeing Company and The Live Well Collaborative.

Lightweight Materials to Aid Sustainability Targets:

The Recaro SL3710 Seating delivers an 8 kg seat that requires 50% less maintenance made up of lightweight materials and recycled leather covers, plus optimized components.

The Ultra Slim concept by Cecence has collaborated with Doy Design to utilize bio-resin in a compression molding process to develop a seat weighing just over 7 kg. The team states the Ultra Slim concept can reduce the overall cabin weight of a short-haul A320 by over 500kg compared to existing lightweight seats on the market.

Read more:Etihad Launches first commercial flight from UAE to Israel

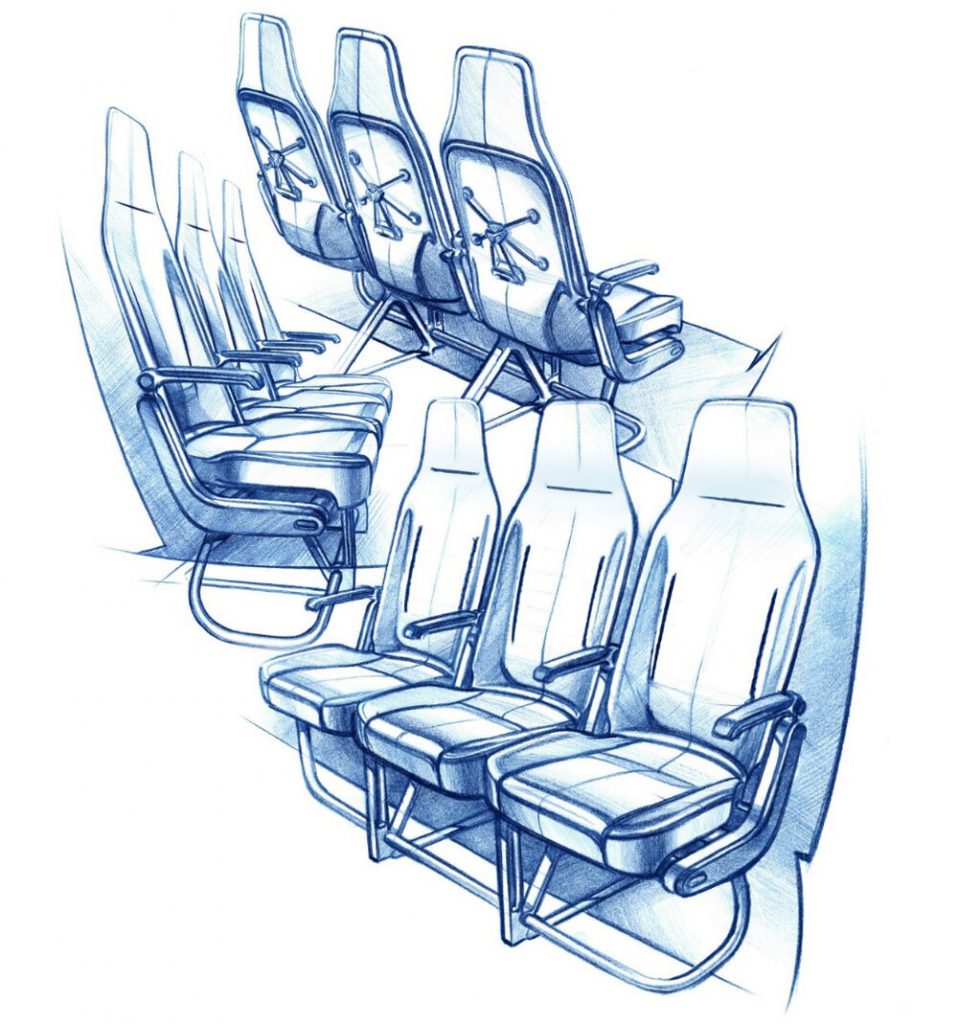

T1-series Seating from Toyota Boshoku:

T1 Series from Toyota Boshoku deliver to create a high-quality time and space in aircraft seating. Toyota Boshoku transfers its automotive knowledge to aircraft seating.

The maverick project, A Touchless future aviation:

Rosen Aviation has announced new sensor and control products to their future product offerings. This signals a new wave of cutting-edge technologies that will reshape the passenger experience across all markets.

Read more: Qantas preparing flights, New Zealand opens skies for Australia

Aerospace

Boeing Transfers Rocket Stage to NASA, Paving Way for Human Moon Mission

Boeing has achieved a significant milestone by providing NASA with the second core stage of the Space Launch System (SLS) rocket.

This crucial component, crafted at NASA’s Michoud Assembly Facility (MAF), is set to propel the Artemis II crew into lunar orbit, marking humanity’s return to deep space after a 50-year hiatus.

The monumental Boeing-built rocket stage, the largest element of the Artemis II mission, will embark on a journey aboard the Pegasus barge, traveling 900 miles to NASA’s Kennedy Space Center.

Comparison of two legendary aircraft B777x vs B747 aircraft:Click here

Upon arrival, it will be meticulously integrated with other essential Artemis II components, including the upper stage, solid rocket boosters, and NASA’s Orion spacecraft within the iconic Vehicle Assembly Building. This intricate integration process is a vital step toward the eagerly anticipated Artemis II launch, slated for 2025.

“Boeing-built products helped land humankind on the moon in 1969, and we’re proud to continue that legacy through the Artemis generation,” remarked Dave Dutcher, vice president and program manager for Boeing’s SLS program. “Together, with NASA and our industry partners and suppliers, we are building the world’s most capable rocket and paving the way to deep space through America’s rocket factory in New Orleans.”

NASA, Lockheed Martin Reveal X-59 Quiet Supersonic Aircraft:Click here

The delivery of Core Stage 2 marks a significant achievement in the evolution of the SLS rocket. Towering over 200 feet and powered by four RS-25 engines, this core stage, coupled with two solid-fueled booster rockets, will generate a staggering 8.8 million pounds of thrust. This immense power is crucial to launching Artemis II and future missions into the vast expanse of space.

The SLS rocket stands unparalleled in its capability to transport both crew and substantial cargo to the moon and beyond in a single launch. Its extraordinary capacity will facilitate the delivery of human-rated spacecraft, habitats, and scientific missions to destinations including the moon and Mars, ushering in a new era of space exploration.

-

Travel1 week ago

Travel1 week agoAir India to Expand US Operations with Three New Routes After a Decade

-

Travel2 weeks ago

Travel2 weeks agoWhy We Should Avoid These Stamps in a Passport

-

Airlines1 month ago

Airlines1 month agoInvestigations Reveal Fake Chinese Titanium in Boeing and Airbus Jets

-

Tech4 weeks ago

Tech4 weeks agoChina’s CATL Plans 1,800-Mile Electric Plane Launch by 2027

-

Airport3 days ago

Airport3 days agoTop 10 Largest Airports in the World by Size

-

Aerospace4 weeks ago

Aerospace4 weeks agoChina’s Fighter Jets Turn Wings into Autonomous Drones

-

Airlines4 days ago

Airlines4 days agoAir India Rolls Out A350s for Delhi-New York JFK and Newark Routes

-

Defence3 weeks ago

Defence3 weeks agoBoeing Enhances Chinook with New Engines and Block II Upgrades at $96 Million