Aerospace

Here are a few things you need to know about ‘Airlander 10’ Worlds biggest Airplane..!

-

1. Bigger than A380

The Airlander 10 the world’s largest flying machine. Airlander 10 is much bigger than the world’s largest aeroplane, an A380, but flies much lower and slower.

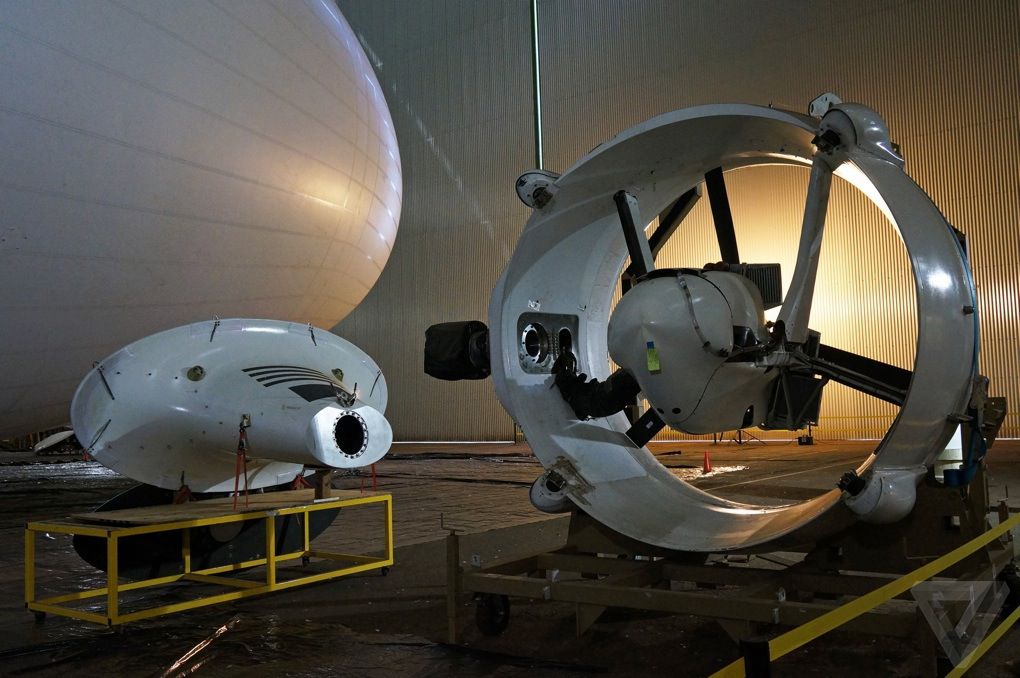

2. ability to carry 10 tonnes

The Airlander 10, named after its ability to carry 10 tonnes, measures 92 metres long, 43m wide and 26m tall. It’s shaped like a traditional airship, made of super-strong carbon fibre and filled with helium to raise it.

3. U.S. Army project

The Airlander was originally developed as a part of a U.S. Army project, but was dropped by the higher-ups in 2012 and it is now being converted into a business that offers leisure flights from a hangar in England’s Cardington, Bedfordshire.

4. How Big is it..!

The 300-foot-long vessel was filled with 1.3 million cubic feet of helium during a test run in October and the engines and fins are being fitted before the aircraft’s first flight with its new specifications next month. The exact date for its flight has yet to be announced, but the craft will be restricted to flying within a 70-mile radius.

5. Woven fabric

Its composition includes a woven fabric for strength on the inside, and a Tedlar layer for protection on the outside, sandwiching a mylar film to retain the helium.Materials used throughout the manufacture of the Airlander 10, range from bespoke hull fabric to the mainly carbon composite mission module; fuel module; ducts, and engine support battens.

5. worth of $1.1 billion

This model alone is worth $1.1 billion and has fairly complex flight systems. The Airlander produces 60 percent of its lift aerostatically (because it is so light) and 40 percent aerodynamically (because of its wing-shape, as well as having the ability to rotate its engines).

6. Special feature.

These features allow the craft to hover as well as land on nearly any surface, including water, desert, and ice. With anything this large, it doesn’t move very quickly (cruising speeds at 90 mph), but it can stay in the air for two weeks at a time and reach heights of 20,000 feet with a 10-tonne cargo.

7. Major Investor.

The project was initially given £60 ($122) million by the US government before it was pulled by the military for being too costly. It was then shipped over to Britain, where it received $26 million of private investment cash including government and EU grants worth $12 million. The project is backed by various celebrities including Iron Maiden frontman Bruce Dickinson and Richard Branson.

8. 1.3 million cubic feet of helium

The vessel was filled with 1.3 million cubic feet of helium – enough to fill 15 Olympic-sized swimming pools – in a test run last October and now the engines and fins are being fitted ahead of next month’s flight. The craft has already been tested with a successful hover test, with the hull being filled with helium and floated outside the aircraft hanger in November, but this will be the first test once the engines are successfully attached.

9. Test flight

The main purpose of the test flight is to start amassing the 200 hours of flight time any new design needs before it is declared airworthy by the Civil Aviation Authority and the European Aviation Safety Agency.

10. Future plans

“It’s very satisfying for the team and me to get another milestone under our belts. We’re hugely excited about the forthcoming Airlander First Flight this year,” Mick Durham, Hybrid Air Vehicles’ Technical director said in a press release. If the flight is successful, this prototype will then go into production.

Liked it ..?

Share with your friends and Family

Aerospace

Which is bigger 777x or 787 aircraft ?

The 777X is a new series of the Boeing 777 family and is designed to be larger and more efficient than its predecessor. It features two variants: the 777-8 and the 777-9, being the larger of the two.

The Boeing 777X emerges as the larger sibling within the Boeing family, representing a significant leap forward in both size and efficiency. Comprising two variants, the 777-8 and the 777-9, the latter takes the crown as the larger of the two. With its expansive fuselage and impressive wingspan, the 777X is tailored for long-range journeys and boasts a substantial passenger capacity.

On the other hand, the Boeing 787, affectionately known as the Dreamliner, occupies a niche in the market as a smaller yet formidable aircraft designed for medium to long-range flights. Its distinguishing feature lies in its composite fuselage, a technological marvel that renders it lighter and more fuel-efficient compared to conventional aluminum counterparts. The Boeing 777X is larger than the Boeing 787 aircraft.

When it comes to passenger capacity, the 777-9 reigns supreme, typically accommodating a sizeable contingent of 400-425 passengers in its standard configuration. In contrast, the 787, with its more modest dimensions, typically carries between 240-290 passengers, depending on the variant and layout.

One of the remarkable innovations introduced with the 777X is its folding wingtips, a feature designed to address the logistical challenges of accommodating such a large aircraft in conventional airport gates. These folding wingtips enable the 777X to retract its wings, allowing it to fit into gates designed for smaller aircraft while still reaping the benefits of an extended wingspan during flight, thereby enhancing fuel efficiency and operational flexibility

Aerospace

China Secures Production Certificate for Mass Production of Pilotless eVTOL Aircraft

The first passenger-carrying pilotless electric vertical takeoff and landing (eVTOL) aircraft in the world, the EH216-S, has received the Production Certificate for its eVTOL aircraft from the Civil Aviation Administration of China (CAAC).

This is a significant milestone for EHang Holdings Limited, the leading UAM technology platform company in the world. This outstanding accomplishment is another big step towards mass manufacturing for the eVTOL aircraft and the ensuing commercial operations, building on the ground-breaking acquisition of the Type Certificate and the Standard Airworthiness Certificate for the EH216-S.

The PC is a crucial certificate that the aircraft maker receives from the CAAC, the country’s aviation authority. By obtaining this certificate, EHang has demonstrated that it has set up a quality management system for mass production that satisfies the airworthiness regulation standards set forth by the CAAC, and the company has been given permission to continue producing mass quantities.

It is also a strong guarantee of the calibre of the goods made by EHang. Raw materials, supplier management, manufacturing organisation, production quality control, aircraft pre-delivery test, after-sales repair and maintenance, etc. are all included in the mass production quality management system for the EH216-S.

To ensure that every aircraft and its components that roll off the production line strictly adhere to the approved type design and safety requirements, the system sets clear guidelines and documentation for every step in the production procedure. This ensures comprehensive traceability and safety control.

Aerospace

Four Airbus A380 Superjumbos lined up to be scrapped

In a strategic move aimed at reclaiming valuable resources from the iconic Airbus A380 aircraft, VAS Aero Services and Dr. Peters Group have announced a significant collaboration.

This partnership marks a milestone in aviation logistics and aftermarket services, with four of these colossal planes slated for teardown and redistribution of used serviceable material (USM).

The venture between VAS Aero Services, renowned for its expertise in aircraft dismantlement, and Dr. Peters Group, a prominent Germany-based investment fund management firm, underscores a commitment to sustainable aviation practices. This isn’t their first foray into scrapping A380s; their successful partnership has already seen the dismantlement of these aircraft, making them pioneers in this niche.

Under the agreement, the latest consignment brings the tally to eight A380s entrusted to VAS by Dr. Peters Group. Managing Director Christian Mailly of Dr. Peters Group emphasized the trust placed in VAS, citing their unparalleled capabilities in dismantlement and aftermarket sales network. It’s a strategic move in response to the growing demand for quality USM parts, particularly with the resurgence in reliance on the A380.

Notably, the teardown process will be carried out at various locations, optimizing the positioning of harvested parts to cater to different markets. While some parts will be positioned in Europe to support operators in the region and the Middle East, others will remain in the Asia-Pacific region. This meticulous strategy ensures efficient access to spare parts, benefiting MROs and airlines across these markets.

The decision to retire these A380s comes at a time when operators are reassessing fleet strategies amidst evolving market dynamics. Despite initial plans for quick retirement due to the emergence of more fuel-efficient alternatives, factors such as a rebound in long-haul demand and delays in new widebody deliveries have prompted operators to reconsider. The A380, with its unique capacity and capabilities, presents a practical solution for short-term capacity management.